One of the most touted claims for electric vehicles is that they are lower maintenance. I want to start right off by saying EVs still need maintenance! There are many issues that can arise with the electrical systems and other parts, and these are very complicated machines. However, it is fair to say that some of the inherent maintenance issues with ICEVs simply don’t exist in the EV world.

Simpler Operation with Fewer Parts & Fluids

EVs have simpler mechanical operation and require fewer parts and fluids. One way to describe an ICE is that it starts with combustion and almost every part after fixes the resulting problems, such as reducing vibration, smoothing output, balancing, dissipating heat, or changing motion from linear to rotational. Electric motors start with a rotating magnetic field, which generates less friction, heat and vibration and is already rotational. As a result fewer parts and fluids are needed for operation.

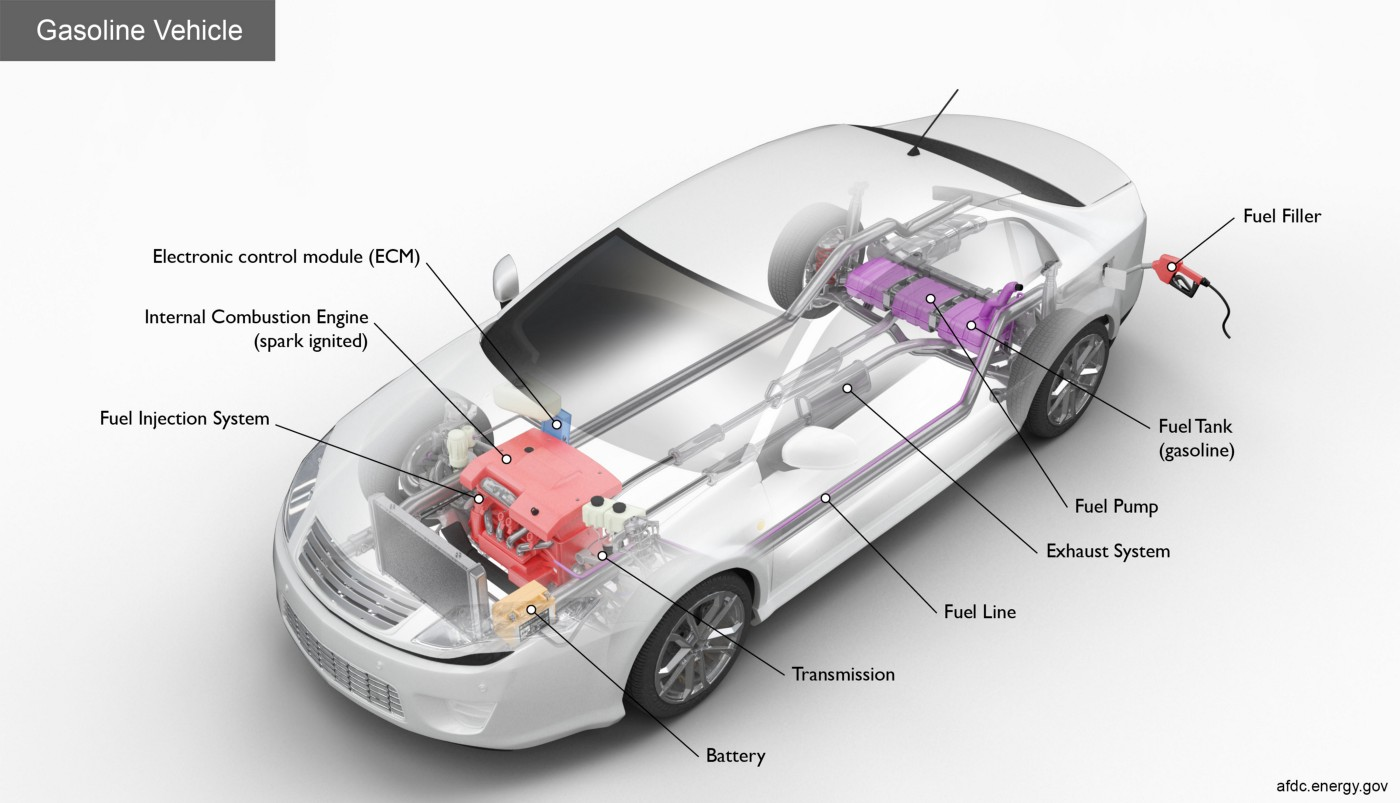

ICEV overview of component:

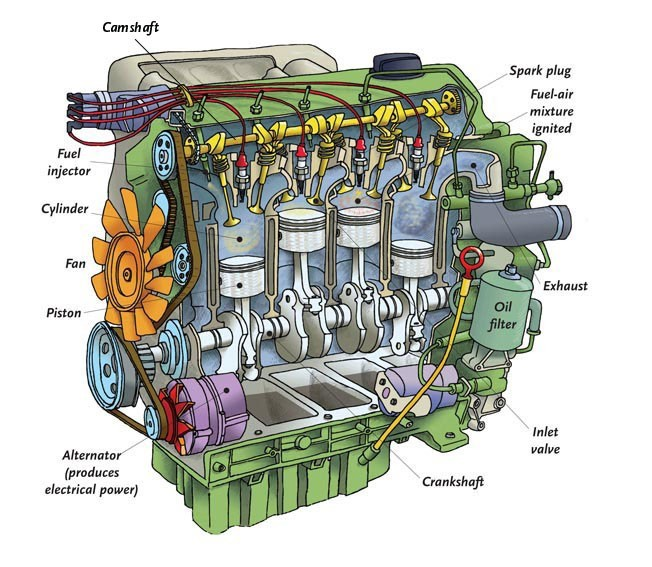

- Internal Combustion Engine: The most obvious part not needed in an EV. ICEs are much heavier (~180 kg) than electric motors (~32 kg). The engine has pistons connected to a counter-weighted crankshaft to convert up-and-down linear motion to rotational motion. Additionally a camshaft is used to open and close valves to allow air to enter and exhaust to leave the combustion chambers. A flywheel is used to smooth inconsistent output from the independently firing pistons.

- Multi-Speed Transmission (manual or automatic): ICEVs only generate good power and torque over a small band of rotation speeds, so a complicated transmission with multiple gears are required to operate across a wide range of speeds. A clutch is needed to decouple the drive axles from the engine while changing gears. In a manual (or standard) transmission, gears are changed by depressing the clutch with a foot and manually moving a gear shift lever. In an automatic transmission, this is all handled by the vehicle, but still requires an internal clutch mechanism.

- Differential: Most ICEVs make use of a complicated limited slip differential, since a buffer is required between the engine and the drive axles.

- Starter: Since ICEs are not self starting, they require a way to start rotating. Ironically, an electric DC starter motor is used.

- Engine oil system: ICEs require oil lubrication to reduce friction on the moving parts in the engine and dissipate extreme heat in the engine, this is stored in an oil pan at the bottom of the engine and is distributed around the engine by an oil pump through a series of valves and an oil filter (which needs to be regularly replaced).

- Engine cooling system: ICEs require liquid coolant to dissipate the heat. This coolant is stored in a coolant tank and distributed through the engine block with a coolant pump and a series of hoses and valves. The coolant is cooled using a radiator mounted at the front of the vehicle. Note that EVs need to cool their batteries and motors, but there is far less heat generated overall.

- Alternator and battery: ICEVs have electricity requirements for the starter motor, lights, electronics and sensors, music and more. An alternator is a type of electric motor used to convert rotational energy from the engine to electricity, which is stored in the 12V starting battery.

- Air intake and exhaust system: To allow for combustion, air is needed. Air is taken from outside through pipes into air filter (which needs to be regularly replaced or cleaned) into the engine. After combustion, exhaust air is drawn out of the engine, routed through a series of pipes, a catalytic converter to remove pollutants, a muffler to reduce the noise and finally out into the air.

- Prop Shaft: The prop shaft is a driveshaft used to move the rotational output from front to back or vice-versa. They are used in front-engine rear-wheel-drive (RWD) vehicle, a rear-engine front-wheel-drive (FWD) or any all-wheel-drive (AWD) ICEVs. They often occupy a ‘tunnel’ that juts into the passenger compartment. The middle passenger in the back seat of a car with this tunnel will feel the reduced leg room. For EVs, the motor/inverter are placed in line with the drive axles, so the only EVs that could require prop shafts would be AWD vehicles with only one motor, but I could not find any manufacturers that use this design, as it is better to just put an additional motor for the extra wheels being driven.

- Fuel Tank: A place to store all your gas or diesel. One advantage is that as you use it your vehicle gets lighter, while in an EV the battery pack weighs the same full or empty.

- Various Fluids: To make all of the systems above work smoothly, we need fluids to both lubricate to reduce friction and dissipate heat. We need engine oil, transmission oil and engine coolant. All of these need regular replacing and can leak or burn off.

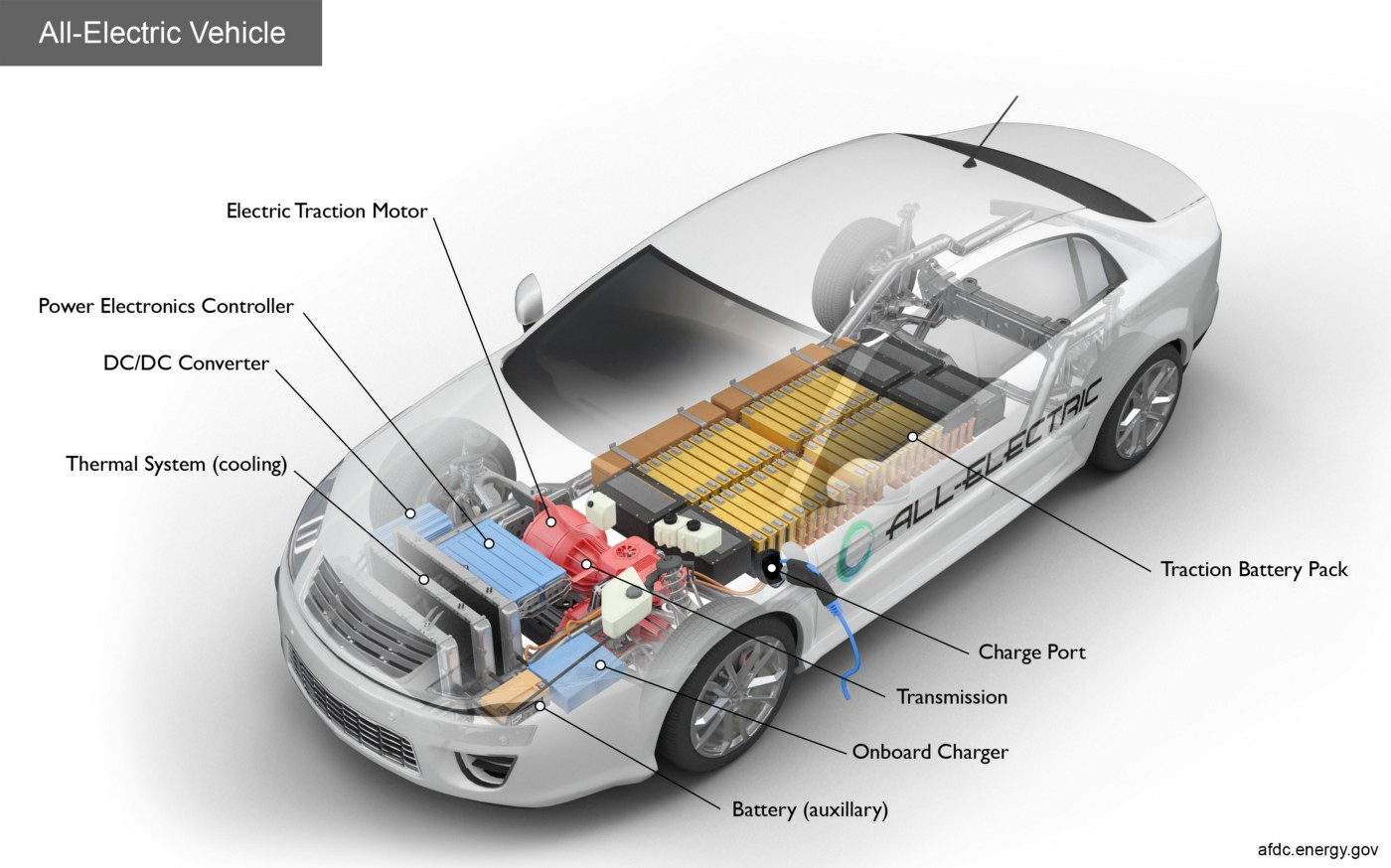

EV overview of components:

- Motor and Inverter: The power output in an EV comes from the inverter and motor combination, as we discussed in the technology section. The output is smooth and precisely controllable rotational motion without the need for any of the extra mechanical parts found in an ICE.

- Single-Speed Transmission: Since EVs generate torque instantaneously and consistently, and have high maximum spinning speeds, EVs can get away with a single-speed transmission which is far smaller and simpler than the multi-speed transmission in an ICEV. Note that some EVs still choose to have multiple gears to optimize acceleration and top speed, such as the 2-speed Porsche Taycan gearbox.

- Open Differential: EVs only need simple and cheap open differential and provide traction control by varying the speed, power and torque of the electric motor and through anti-lock braking.

- Charge port and charger: A charging port is used whenever adding energy to the car from outside. An onboard AC-to-DC charger is needed to convert AC power to DC power to charge the batteries (at home or at AC charge points). The charger is not used when directly connecting to DC Fast Charging stations.

- Battery Pack: The heart of the energy storage of an electric vehicle is the battery pack. It has no moving parts and is typically build into the subframe of the vehicle. It requires protection, fire walls, and coolant channels to dissipate (or provide) heat to the battery pack.

- Fluids: EVs still need some lubricants, such as inside the rotating components of the motor and coolant for the motor and battery packs. However, these systems rotate smoother and generate less heat so these fluids do not need to be replaced as frequently and are less likely to leak.

Battery Life & Degradation

Batteries degrade over time. Geotab did an analysis of over 6000 EVs, and found high levels of sustained battery health, and that most batteries are on target to outlast the vehicles. Batteries can be degraded by overheating and extreme cold, frequent fast-charging and operating at near-full or near-empty capacity.

There are many approaches that increase the longevity of a battery pack:

- Thermal management to avoid overheating, such as liquid cooling.

- Avoid extreme cold, and pre-condition the battery pack (basically pre-heating) before driving.

- Avoid extreme heat, and park in the shade wherever possible.

- Minimize DC fast charging, using it only for road trips.

- Avoid operating at near full or near-empty. Manufacturers build buffers of battery charge both below 0% and above 100% for this reason. In addition, many manufacturers let the owner set a charge limit which can be over-ridden when extra charge is needed for longer trips.

Brake Longevity

One of the main advantages of regenerative braking is that brakes are used far less than in an ICEV. This reduces pad wear and increases their life. Interestingly, new problems arise as a result:

- The adhesives holding the pads together break down over time. This is not normally an issue with traditional brake pads because they need regular replacement due to wear.

- Since EV brake pads are used less, they accumulate corrosion from moisture. A traditional brake pad heats up, dissipates moisture and rubs rust off the pad face.

At least one brake pad manufacturer has come out with special pad designs for EVs taking these problems into account.

Ease of Repair and Right-to-Repair

Electric vehicles require different skillsets to repair than an ICEV. Most importantly, high voltages and currents from battery packs can kill a person working on an EV without proper protective equipment and training.

Manufacturers (especially Tesla) have been reluctant to allow or enable third party mechanics to repair their vehicles, and also do not want people working on them at home. However, the constrained competition results in longer wait times, and third party repair shops tend to be more expensive than their ICEV counterparts for similar repair jobs.

The ‘Right to Repair’ movement is fighting for consumers and third parties to be able to repair their cars, with access to service manuals, diagnostic tools, ability to source parts and training.

Next, on to Environment!

Header image credit: Neon Brand